System

Smart Automation Leader - DrimSys

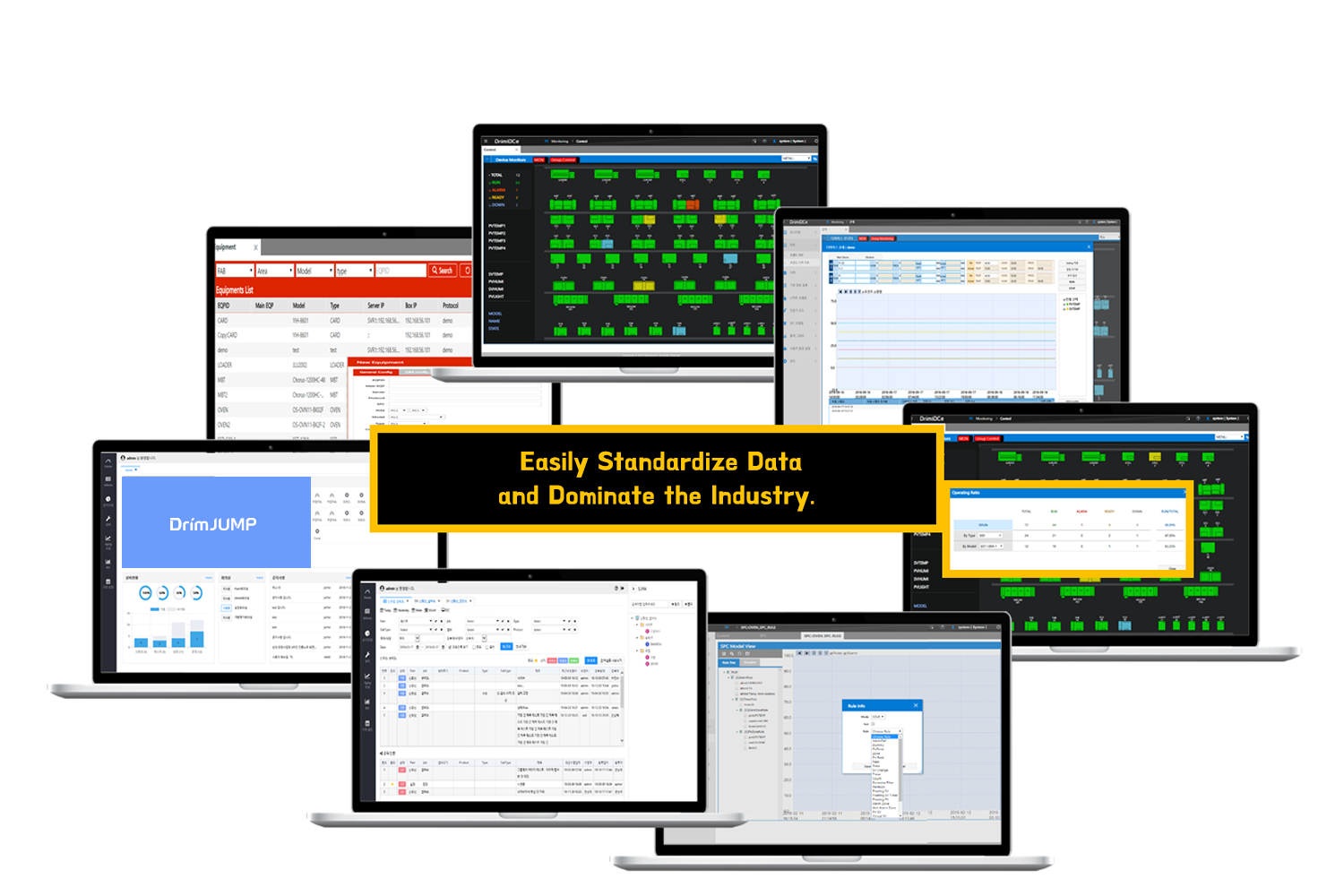

DrimJUMP

Overview

DrimJUMP controls of information about every device (sensor, equipment, system) within a factory, provides an easy feature to save the information, control status, sense disorder, and operate, and easily establishes a customized factory operation system.

Feature

- Factory Operation Control

- Dash Board

- Real Time Status Monitoring

- Real Time Trend Chart

- Trend History Chart

- Trend Histories

- Alarm Histories - Factory Operation Disorder Sensing

- Real Time Data’s Disorder Status Sensing via Modeling Rule Creation (Rule Tree)

(Alarm Creation by Rule Tree)

- Visible & Audible* Alarm Notification

- Alarm Confirm & Release

- Alarm History Management

- Mobile Alarm Notification - Disorder Sensor Control

- EQ Start & Stop by Operator

- EQ Automatic Start & Stop by Operator Process Management Rule - Equipment Operation Rate Status

- Operation rate by each equipment status

- Operation / alarm / ready / down (Equipment Status Ratio) - Factory Operation Collaboration

- Each part operator collaboration information management

- Each part collaboration knowledge saving Documentation saving and link support Collaboration status management - Statistical Process Management Logic Modeling

- Statistical process management logic operation using Rule Tree (Rule Logic Operation)

- Statistical process management simulation (Rule Simulation) - Equipment Modeling

- Location Information (大分類) (FAB)

- Location Information (小分類) (Area)

- Equipment Model / Type / Protocol

- App Server Edge Dominator Variable - Statistics Graph

- Statistical Dispersion

- Equipment Connection Status Dispersion (Up Down Dispersion)

- Change Probability Density - Report

- Weekly / Monthly Report Creation & Print

- Usable if certification organizations such as HACCP regularly report documents about temperature to the government organizations.

Related Product * Click the image below to a detailed page.

Reference

- Samsung Electronics Onyang 3Line DrimJUMP 1.0 (before, DrimIDCe) Establishment

- Samsung Electronics Onyang 4Line DrimJUMP 1.0 (before, DrimIDCe) Establishment

- Samsung Electronics Cheonan 5Line DrimJUMP 1.0 (before, DrimIDCe) Establishment

Application Client

- Samsung Electronics